Table of Contents

Determination of flying number of satin fabric

In order to construct a regular satin fabric weave correctly, the flying number s should be selected after the tissue cycle number R is determined. For example, to draw an 8-piece satin weave, i.e. r = 8, the flying number s is selected by dividing the complete yarn number r into the sum of two numbers.

For example, 8 can be divided into four groups: 1 + 7, 2 + 6, 3 + 5 and 4 + 4. According to the above conditions, s must be 1 < s < R-1 and there can be no common divisor between S and R. in these four groups of data, only 3 and 5 can be used as the flying number, so there are 8 3 flying and 8 5 flying for 8 Satin structures.

Generally, there are 5, 8, 10, 12, 16 satin fabrics in common use.

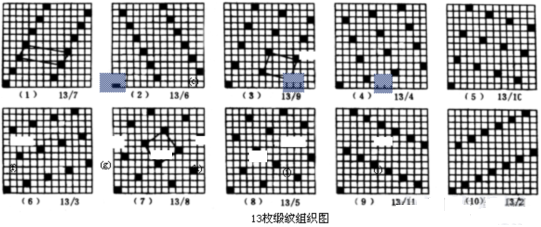

In order to analyze the advantages and disadvantages of the arrangement of satin fabric weave points, the 13 satin weave diagrams with large tissue cycle shown in the figure below are illustrated as an example.

The flying numbers of 13 Satin patterns can be divided into five groups: 2 + 11, 3 + 10, 4 + 9, 5 + 8 and 6 + 7, that is, 10 different Satin patterns are drawn with the flying numbers of 2 and 11, 3 and 10, 4 and 9, 5 and 8, 6 and 7 respectively.

It can be seen from these figures that (a) and (b), (c) and (d), (E) and (f), (g) and (H), (I) and (J) are similar in pairs and become similar Satin texture.

The so-called similar satin weave means that in the same group of satin weave, if any satin weave is rotated 90 º clockwise or counterclockwise, the meridional and latitudinal flight numbers of the two weave are consistent, only the starting point positions are different

It can be seen from the figure that figure (a), (b), (I) and (J) are the satin fabric texture with the worst effect because their organizational points form an obvious inclined path.

The effects of (c), (d), (E) and (f) in the figure are good; In the figure, the effects (g) and (H) are the best, and the distribution of tissue points is the most uniform.

Connecting the four adjacent points in the three organization charts (a), (c) and (g) of the graph, it can be seen that (a) a longer parallelogram is formed in the graph, (c) a shorter parallelogram is formed in the graph, and (g) a square is formed in the graph.

This shows that when the organization points are distributed into a square in the satin fabric weave, the organization points are evenly distributed on the fabric surface, and the diagonal trace generated by the organization points is not obvious, which can improve the smoothness of the satin fabric surface.

To sum up, when selecting satin fabric weave, it is best to have square distribution of weave points, followed by diamond distribution, and worst to have parallelogram and rectangle distribution, which should be avoided as much as possible.

The above analysis is carried out when the warp and weft densities are equal.

If the warp and weft densities of fabrics are different, the quadrilateral formed by adjacent tissue points in satin weave will also change.

At this time, appropriate satin weave should be selected according to the specific situation in order to achieve good effect.

Organization chart drawing

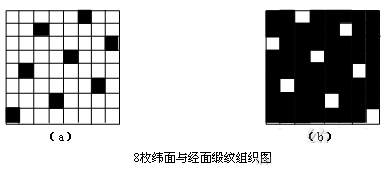

As mentioned above, the satin fabric weave can be divided into warp satin and weft satin.

The fabric with warp floating yarn on the front is called warp satin, and the fabric with weft floating yarn on the front is called weft satin.

The warp and weft on the front and back of satin weave interact with each other.

Figure (a) shows 8 / 3 weft satin weave, while figure (b) shows 8 / 5 warp satin weave. In the figure (a) and (b) are opposite to each other.

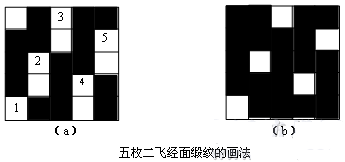

Drawing steps of 5 / 2 warp satin

When drawing the warp surface satin fabric pattern, the warp surface Satin pattern is drawn by the warp flying number, and the weft surface Satin pattern is drawn by the weft flying number.

As shown in figure (a), it is the drawing method of 5 / 2 warp satin.

Figure (b) shows the drawing method of 5 / 3 weft satin.

① Determine the number of R as 5;

② Draw warp organization points continuously at “1” on the first warp, leaving one weft organization point;

③ Count “2” along the warp direction to determine the starting point of warp organization point on the second warp;

④ Count the flying number upward at the starting point “2” of the warp organization point of the second warp, make the starting point “3” of the warp organization point of the third warp, and so on. As shown in figure (a). Figure (b) is a warp satin weave drawing with the weft weave point as the starting point.

It first determines the weft organization point on the first weft, then flies “2” along the weft direction to determine the weft organization point of the second weft, and so on.

2. Drawing steps of 5 / 3 weft satin

① Determine r as 5;

② Draw the warp organization point from “1”;

③ Count “3” to the right along the weft direction, draw the warp point on the second weft, and so on. According to the organization of five three flying weft satins in Figure 2-13, when SW = 3, SJ = 2.

To sum up, we summarize as follows: when drawing satin fabric weave, take the lower left corner of the large square with RJ = RW = R circled on the grid paper as the starting point.

When drawing according to the warp flying number, move a warp (a row of longitudinal grid) to the right from the starting point, and count SJ small grids upward (or downward) to get the starting point of the second floating long line, then find the third tissue point according to SJ on a warp moved to the right, and so on until a tissue cycle is reached.

When drawing according to the flying number in the weft direction, move a weft yarn (a row of horizontal grid) upward from the starting point, and count SW small grids to the right (or left) to obtain the second individual tissue point, and so on until a tissue cycle is reached.